Product Review

Product Review

-

Until PAC’s Formation

SamWoo’s PAC uses bauxite as a raw material, manufactured in accordance with the BAYER Law. Bauxite is a basic inorganic macro-molecular flocculation agent formed from the reaction of hydrochloric acid with pure aluminum hydroxide. SamWoo’s PAC division develops its people’s manufacturing skills and manufactures products with a wide range of flexibility and economic efficiency to meet each demand. The company’s PAC is also an excellent product with a high degree of purity and that undergoes a strict manufacturing process.

-

Composition and Structure

PAC is expressed as [(Al₂(OH)nCl₆-n)m], in which n: 1≦n≦5 and m: m≦10 and the basicity of which is n/6x100%, In an aqueous solution, It become a coordination compound with [Al(H₂O)₆], and become a polynuclear compound using OH as a bridge. As its nucleus gets larger, it forms a gigantic inorganic macromolecular compound.

Distinctive

-

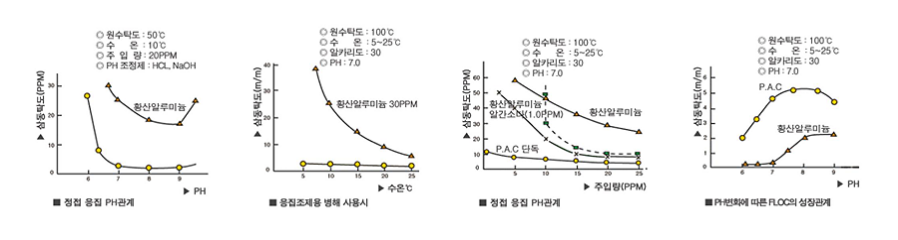

Very rapid agglutination and precipitation of FLOC

As the aluminum in PAC forms solubly active polynuclear ions due to its intermediate condensation reaction form the start, the time in which FLOC forms and precipitates is very rapid, and its adsorption characteristic is very strong. It forms a very large FLOC and demonstrates very strong adsorption characteristics. Therefore, the time for its stirring, blending, stopping and precipitating is greatly reduced.

-

Efficacy in water treatment with low alkali winter

As its agglutination ability does not drop in water with low alkali in winter, no additional precipitation agent is needed in water treatment of cold areas.

-

Non-necessity/reduced need for preparation of alkali and accelerating agent for agglutination

Since PAC is basic, alkali reduction and pH drop after its addition are not significant. Therefore, the need to prepare is significantly reduced or is usually even unnecessary. Therefore, the efficacy of a single treatment with PAC is excellent, compared to using aluminum sulfate jointly with an agglutination-accelerating agent such as active silicate and bentonite.

-

Restoration of original scent and color

PAC is very effective in treating sewages containing large amount of mineral and organic substances compared to aluminum sulfate.

-

Reduction of agglutination treatment costs

Sine PAC is an effective inorganic macromolecular agglutinating agent, up to 1/1.5~1/2 can be saved with it than by using aluminum sulfate. It is also cost-effective, since no alkali agent and agglutinating agent is necessary. Especially, it has superior economic efficacy because it reduces the costs of transport and water treatment and increase the efficacy and satety of the agglutination treatment.

-

Simplification of operation and rationality of equipment

With PAC, the acceptable limits for the appropriate infusion amount and flexibility for change in the quality of water are generous. PAC increase treatment efficacy and safety and therefore simplifies the operation and rationally of equipment.

-

De-fluoridation

FT-1700 contains an additional de-fluoridating agent and is manufactured for superior treatment of elements containing fluorine.

-

High purity and good quality

It has a high degree of purity and good quality compared with heavy mercury and arsenical.

Products Standard

| item | Typical specification for tab water (KS M 1510-1998) | Our specification | |

|---|---|---|---|

| Tap water | FT-1700 | ||

| Appearance | Colorless/yellowish light brown transparent liquid | Light lemon-yellow transparent liquid | Light yellowish transparent liquid |

| Gravity(20℃) | 1.19 or more | 1.22 or more | 1.30 or more |

| pH(1W/V%) | 3.5~5.0 | 3.8~5.0 | 3.5~5.0 |

| Al₂O₃(%) | 10.0~11.0 | 10.0~11.0 | 15.0~17.0 |

| Basicity(%) | 45~60 | 45~60 | 45~65 |

| Sulfuric ion(%) | 3.5 or below | 3.5 or below | 3.0 or below |

| Ammonia nitrogen(%) | 0.01 or below | 0.004 or below | 0.01 or below |

| (Fe)(%) | 0.01 or below | 0.005 or below | 0.01 or below |

| (As)(ppm) | 1.0 or below | 0.5 or below | 1.0 or below |

| (Mn)(ppm) | 15.0 or below | 1 or below | 15.0 or below |

| (Cd)(ppm) | 1.0 or below | 0.2 or below | 1.0 or below |

| (Pb)(ppm) | 5.0 or below | 1 or below | 5.0 or below |

| (Hg)(ppm) | 0.1 or below | 0.02 or below | 0.1 or below |

| (Cr)(ppm) | 5.0 or below | 1 or below | 5.0 or below |